TV Station NHK

Science Zero The Underground Secrets of Oze

DC292042![]()

サイエンスゼロ 大調査!尾瀬 知られざる地下世界 [NHK]

![]()

![]()

|Length : 30min |Year : 2020 |

Science ZERO utilizes cutting edge knowledge and technology to thoroughly investigate various phenomena from a scientific perspective. In this episode, we focus on Oze, Japan’s largest mountain wetlands, where a comprehensive scientific survey was conducted after a hiatus of 20 years. Documenting the survey team for one year, this program joins them in revealing the secrets that have made Oze a paradise for rare flora and fauna. Even the experts are surprised by what they find in a pond called Ryugu Pond. How can this small pool possibly keep absorbing a stream of water that continually eddies in? Using the latest underwater drone technology, the survey team discovers a complex tunnel structure beneath the pond. It turns out that the key to Oze’s unique ecosystem can be found in an unknown subterranean world!

The Chip Challenge

DC290427![]()

復活なるかニッポン半導体 [NHK]

![]()

![]()

|Length : 49min. |Year : 2004 |

Although Japan once dominated the global market for semiconductors, a fierce price war left Korean, Taiwanese and other manufacturers in control while the Japanese semiconductor industry fell into a slump. Now Japan is fighting back by harnessing a traditional industrial strength: unshakable determination to develop superior technologies. The programme focuses on the world of mobile phones, where high-performance semiconductors hold the key to international success.

Masterly Skills | The Lustre of Edo-Kiriko

Masterly Skills | The Lustre of Edo-Kiriko

DC290324![]()

技~極める | 光彩を彫る 江戸切子職人・小林英夫 [NHK]

![]()

![]()

|Length : 24min. |Year : 2003 |

The skill of Japanese traditional style of cut-glass 'Edo-Kiriko', originated in Edo period, has been handed down to some craftsmen today. Kobayashi, aged 79, is one of them, having dedicated his energy to this work for over fifty years. He has a super skill to give a dazzling brightness to his creation by controlling the way of cutting. His work has a warm, refined, but sharp feel, that is a brilliant glass art with reflected light, which attracts many craftsmen in this field.

Masterly Skills | Hand-Made Fountain Pens

Masterly Skills | Hand-Made Fountain Pens

DC290323![]()

技~極める | 手作り万年筆 ミクロの技人・植原榮一 [NHK]

![]()

![]()

|Length : 24min. |Year : 2003 |

Today, there are only a small number of craftsmen who make fountain pens all hand-made. Uehara, aged 82, has been engaged in this work since he was 19. He makes special fountain pens that fit perfectly in the hand of each customer, taking each person's particular handwriting into consideration. His skill of adjusting the pen point, using a loupe, is remarkable, because a difference of 0.01 millimeters does affect the smoothness of writing.

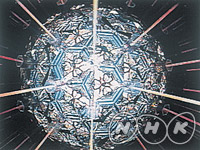

Masterly Skills | Kaleidoscopes Reflect the Universe

Masterly Skills | Kaleidoscopes Reflect the Universe

DC290317![]()

技~極める | 宇宙を映す万華鏡 [NHK]

![]()

![]()

|Length : 24min. |Year : 2003 |

We remember, in our childhood, we were fascinated with the unexpected beauty we find the moment we looked into the kaleidoscopes. Today, kaleidoscopes are recognized as an art from in many countries, and particularly in the United States, they are often used for medical instruments for healing people. Koji Yamami, a professional kaleidoscope maker, won the Grand Prix at the kaleidoscope convention held in the US in 2001.